The Efficiency Paradox: Why Construction Fell Behind Agriculture

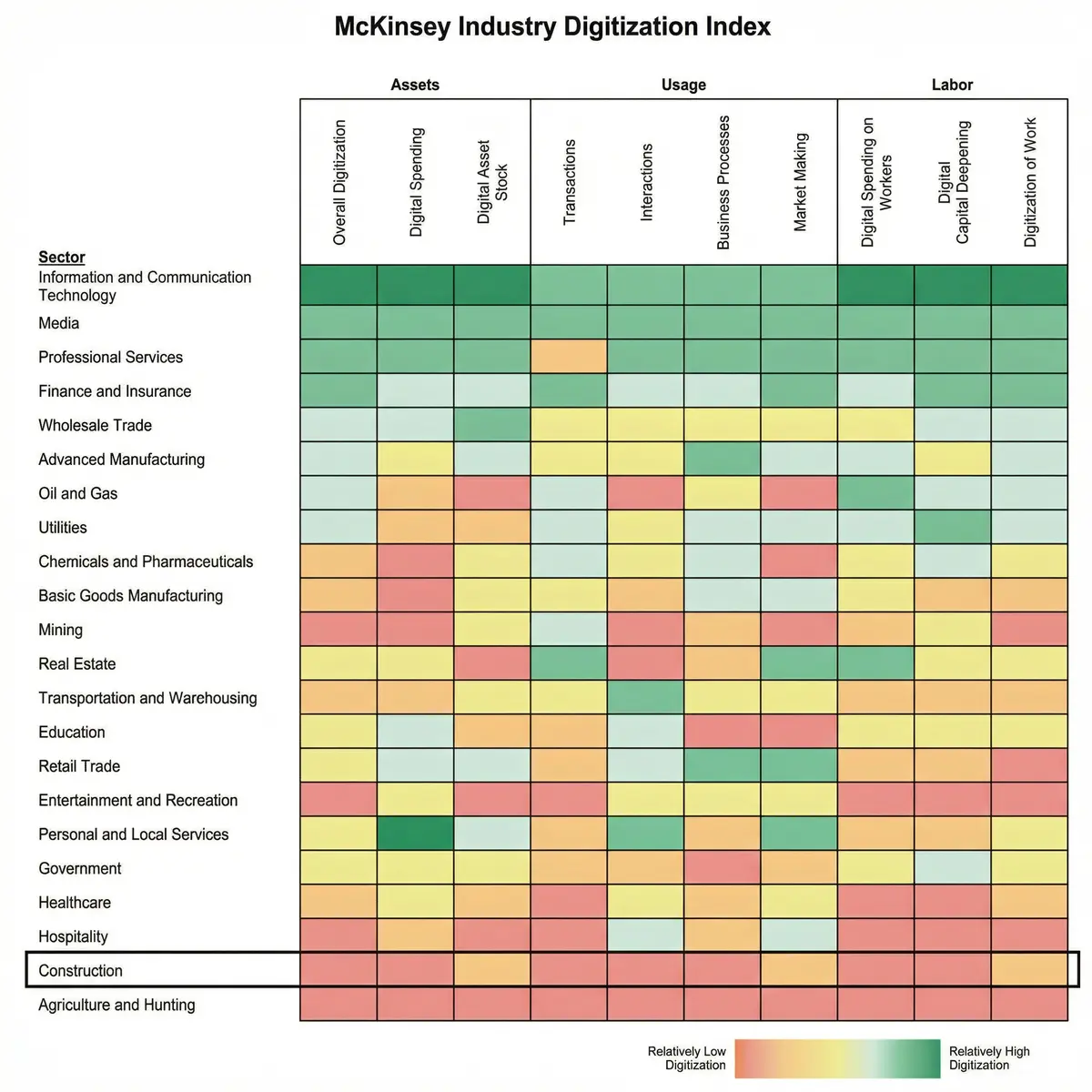

Do you remember the groundbreaking report published by the McKinsey Global Institute (MGI) back in 2017 titled "Reinventing Construction: A Route to Higher Productivity"?

In that report, global industries were ranked according to their "Digitization Index." At the very bottom of the table, two sectors stood out for having the least digital assets, usage, and labor:

Figure 1: A visualization based on MGI's Industry Digitization Index.

Construction appeared just above Agriculture.

At the time, it was a small consolation for the construction industry to be slightly more tech-savvy than farming. However, as we moved into the 2020s, data from both McKinsey and the European Investment Bank (EIB) revealed a shocking reality: the positions had flipped.

The Great Divergence: 1% vs. 1500%

To understand why construction is now considered the "last frontier" of digitization, we must look at productivity growth, not just software usage.

According to global economic data spanning from 1947 to today, the Agriculture sector has increased its productivity by over 15x (1,500%). In stark contrast, the Construction sector has remained virtually flat, averaging only 1% growth per year over the last two decades. In some major economies, construction productivity has actually declined.

The Reality Check: While a modern farmer can manage hundreds of acres with a tablet and autonomous drones, a construction site manager often still relies on the same tools used in the 1970s: a clipboard, a radio, and fragmented spreadsheets.

How Farming Overtook Building (AgriTech 4.0)

While construction was debating the adoption of basic BIM (Building Information Modeling) standards, agriculture quietly underwent a massive revolution known as Precision Agriculture.

- Autonomous Fleets: Tractors and harvesters became self-driving robots guided by GPS with millimeter precision.

- IoT & Big Data: Sensors in the soil now measure moisture and nutrient levels in real-time, sending data to the cloud.

- Predictive Analytics: AI models predict crop yields and weather risks months in advance.

This surge propelled agriculture up the digitalization ladder, leaving construction isolated at the bottom.

Why is Construction Stuck?

Why is it so hard to digitize a construction site compared to a farm or a car factory? The McKinsey report and industry experts point to three unique structural barriers:

1. The "Unique Prototype" Problem

Every construction project is unique. Unlike a factory line producing millions of identical phones, every building has a different design, different site conditions, and different regulations. This makes standardization difficult.

2. Extreme Fragmentation

A typical project involves dozens of subcontractors, architects, engineers, and suppliers. These teams often work in silos, using different software that doesn't "talk" to each other. Data is lost every time it is handed over from one team to another.

3. The Transient Workforce

Construction relies heavily on temporary, manual labor. Training a workforce on complex new technologies for a project that lasts only 6 months is often seen as a bad investment by short-sighted firms.

The Cost of Inefficiency

The reason for ranking last isn't just a lack of robots; it is a disconnection in information flow. The EIB Investment Survey (2021) highlighted that construction firms are the least likely to adopt digital technologies for data management.

The consequences are expensive:

- Cost Overruns: Large projects typically finish 80% over budget.

- Time Delays: 20% longer completion times than scheduled.

- Waste: Disorganized logistics lead to massive material waste.

The Good News: Because the baseline is so low, the potential for improvement is massive. Digitization can reduce construction costs by up to 15% and reduce project schedules by 30%.

Technology is Not a Luxury, It's Survival

This brings us to the modern era of Construction Tech. The goal is no longer to turn every worker into a computer scientist, but to create tools that are as intuitive as the apps we use in our daily lives.

When we built YAPL, we focused precisely on this "fragmentation" problem. We realized that the industry didn't need more complex tools; it needed a Single Source of Truth.

How YAPL Bridges the Gap

Just as AgriTech connected the tractor to the satellite, YAPL connects the field to the office:

- Real-time Collaboration: Eliminating the "I didn't get that email" excuse.

- Centralized Data: Replacing scattered Excel sheets with a unified dashboard.

- Mobile First: Designed for the engineer in the mud, not just the manager in the office.

Conclusion: Learning from the Farmers

Regardless of your niche in the built environment, strengthening your digital infrastructure is no longer a choice—it is a matter of survival. The gap between the "digital leaders" and the "laggards" in construction is widening every day.

For those who want to escape the bottom of the list and aim for peak productivity, the blueprint exists. It’s time to bury the clipboard and build the future.

YAPL is here to help you lay that foundation.

Ready to boost your site's efficiency? Start your free trial with YAPL today and join the digital transformation.

Related Articles

Ready to Improve Your Project Management?

Try YAPL free for 14 days and put these insights into practice.

Start Free Trial